Waste input.

The packaging from the extended waste separation bins arrives by truck and is fed into the automated sorting line by machine operators.

Separator and unpacker

To remove large cartons and cans.

Ballistic and optical separators.

Are used to separate flat bodies from hollow bodies, then packages according to their chemical composition. The separators are constantly adjusted by maintenance staff.

Manual sorting cabin.

The importance of people. The recovery agents remove the sorting errors to ensure an expected level of quality, ensuring the ultimate expected quality of separation by materials.

Baler.

Bales separated by material, then transported to factories that will transform these bales into secondary raw materials that will ultimately be used to manufacture new objects.

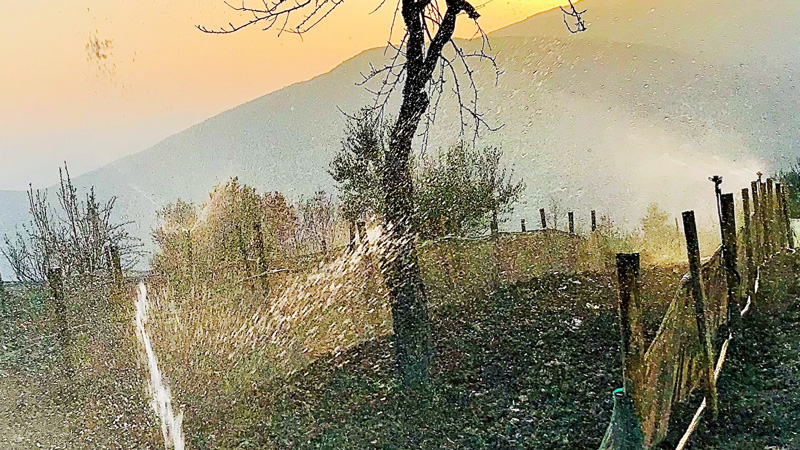

Water-saving irrigation of the enclosures.

Provided by rainwater recovery on roofs and irrigation by misting and rain: Irrigation of production only during 3 months. 50m3 of water/m2/year.

Extraction of cruelty-free slime.

Recovery of snails by means of a differential humidity process on wooden pallets. Slime extraction by gentle ozonisation and steam method, respecting the snails' well-being.

Production of cosmetics based on snail slime.

Anti-ageing skin benefits against tissue slackening, thanks to healing and regenerating properties

Innovative slow-food gastronomy and taste education.

Gastronomic innovation through the creation of dishes including snails, education in taste and the entire production cycle according to the principles of the blue economy.